If you are working on an intravascular catheter, there is one standard you need to be familiar with: ISO 10555. This international standard sets the bar for testing catheter performance and plays a key role in design verification and regulatory approval.

At Medical Murray, we design and manufacture advanced catheters every day. Our testing capabilities are built to meet ISO 10555 requirements with accuracy, efficiency, and confidence.

What Is ISO 10555?

ISO 10555 is the international standard for performance testing of intravascular catheters. It includes several parts that apply to different catheter types.

- Part 1: General requirements

- Part 3: Central venous catheters

- Part 4: Balloon dilatation catheters

- Part 5: Over needle peripheral catheters

- Part 6: Subcutaneous implanted ports

- Part 7: Peripherally inserted central catheters

- Part 8: Extracorporeal blood treatment catheters

ISO 10555 testing evaluates how your device performs under stress and during clinical use. Key tests include:

- Tensile strength and bond integrity

- Balloon fatigue and burst pressure

- Corrosion resistance

- Leakage testing and flow rate measurement

- Dimensional accuracy and tip safety

Why ISO 10555 Testing Matters

Passing ISO 10555 testing is critical for more than just regulatory compliance. It confirms that your catheter is ready for:

- FDA and CE approval

- Clinical trials

- Manufacturing readiness

- Real world performance and safety

This is one of the most important ways to reduce risk in the development process.

How Medical Murray Supports You

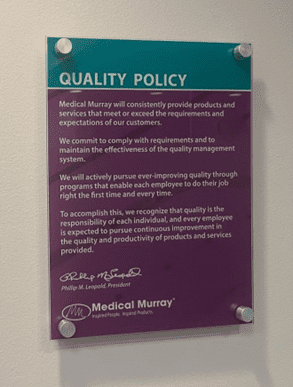

We have invested in testing capabilities that deliver accurate and reliable results. Medical Murray is ISO/IEC 17025:2017 accredited, which means our testing processes meet the highest international standards for precision and traceability.

Our support includes:

- Custom test fixtures built for your unique catheter designs

- Class 7 cleanrooms that maintain sterile barrier conditions

- Regulatory and quality experts who interpret results and prepare reports

- Design verification reports that align with ISO 13485

Whether you are developing a neurovascular microcatheter or a balloon catheter for vascular intervention, our team can help guide your project through verification.

When Standard Testing Is Not Enough

Today’s catheter designs are more advanced than ever, often requiring testing that goes beyond the standard. At Medical Murray, we routinely support custom catheter testing protocols for devices that include:

- Steerable or flexible shafts

- High pressure or compliant balloons

- Novel coatings

- Embedded sensors

We take a flexible, engineering driven approach to make sure your device meets both performance and compliance goals.

Contact Our Team

Are you preparing for ISO 10555 testing? Whether you are early in development or finalizing your submission strategy, we are ready to help. Contact Medical Murray today to get started.