Medical Murray | Complex Catheter and Implant Solutions

Manufacturing pediatric catheters isn’t just about shrinking things down. It’s about rethinking the design, materials, and entire manufacturing process to work safely and effectively in smaller, more sensitive anatomy. At Medical Murray, we’ve worked on a wide range of pediatric medical devices, from neonatal vascular access to congenital heart repairs, and we’ve learned how different these projects can be.

Below are the key things we think about when building pediatric catheters, from the dimensions to the regulatory, and how we take it on with our team, equipment, and processes.

Biggest Challenges When Manufacturing Pediatric Catheters

Pediatric catheters can be as small as 2 – 4 French in size, similar to many neurovascular devices. That kind of miniaturization isn’t always easy:

- Precision matters. Custom extrusion with lower limit wall thicknesses are often needed to keep lumens open without leakage or cross-talk.

- Complex features still need to fit. Some of these small multi-lumen catheters still need to combine reinforced shafts with sensors, balloons, etc. This can require us to get creative with layering, bonding, and assembly.

- Tooling isn’t off the shelf. Almost every one of these micro catheter projects requires custom tools to meet tight tolerances with delicate parts.

Choosing the Right Materials for Pediatric patients

Kids’ bodies are still developing, which means materials have to be safe, soft, and reliable:

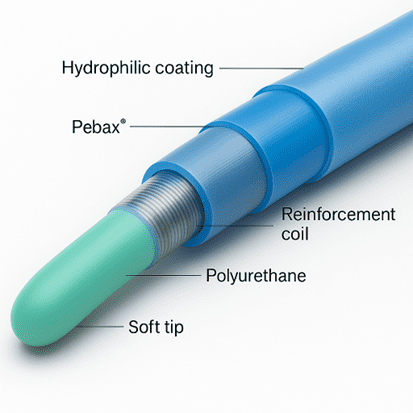

- We often use softer materials. Each material will be chosen based on the flexibility, strength, and compatibility needed for the application, with the outermost material commonly Pebax, nylon, polyurethane, or silicone.

- Soft tips. We often thermoform or mold a softer, atraumatic tip for the distal end and use different durometers along the catheter to make the distal tip gentle enough to reduce trauma.

- Coatings are key. Hydrophilic coatings or lubricant additives help reduce insertion forces, especially in vascular catheters.

We also pay close attention to how materials behave during sterilization, e.g. fluoropolymers don’t do well with gamma or e-beam, so EtO will be used instead.

Creating an Effective Pediatric Medical Device

Even with the small size, pediatric catheters still need to perform:

- They have to be pushable, steerable, and strong enough to get to the right place in the body without kinking or breaking.

- We add reinforcement (like stainless steel or nitinol coil winding or braiding) scaled down for pediatric needs, without making the device too stiff.

- Fluid flow matters. With smaller lumens, we often need to scrutinize flow to make sure irrigation, aspiration, or infusion works the way it should. Since flow is so sensitive to sizing, there can be a noticeable change in flow rates within the tolerance window of these small extrusion lumens.

Cleanliness, Sterility, and Device Testing

Pediatric patients are especially vulnerable, so we treat cleanliness and safety as top priorities:

- Sterilization needs to be material friendly. Most pediatric devices are sterilized with EtO to avoid degrading any radiation sensitive polymers.

- Every process step is scrutinized. We document and test everything, e.g. bond strength, lumen patency, coating durability, and more.

We build our pediatric devices in ISO class 7 cleanrooms, and we provide full traceability on materials and processes for regulatory and quality needs.

Regulations That Protect Pediatric Patients

The FDA takes pediatric devices seriously, and so do we. That means:

- Following design controls from day one, with traceable documentation for everything from risk analysis to verification testing.

- Designing for usability, especially when the device will be used in emergency situations or by staff who aren’t pediatric specialists.

- Supporting rare indications. Sometimes, the volume is low because the condition is rare. We support limited use exemptions and IDE pathways, when needed.

Building Smaller Batches

A lot of pediatric catheters are low-volume, high-impact products. Medical Murray is happy to support it.

- We have production lines that can build small lots of hundreds (or tens) of devices. That often includes hand assembly, micro tooling, and custom test fixtures.

- We iterate quickly. Our team can go from CAD to bench-tested prototype in a couple of months and then iterate in weeks rather than months.

- We keep costs in check with a phased approach, reducing custom parts where we can, and thinking ahead to scaled manufacturing, even when full-scale production may be years away.

Partner with an Expert Pediatric Medical Device Manufacturer

Designing and building pediatric catheters requires precision, patience, and a real understanding of the needs of small patients. It’s one of the most rewarding types of work we do.

If you’re working on a new device for pediatric use, whether it’s early-stage or ready for manufacturing, we’d love to help. Let’s make it real, and let’s make it safe for the kids who need it most.