When you’re developing a complex medical device, especially a Class III product, testing should be part of the process from the very beginning, not something you scramble to do at the end. At Medical Murray, we believe good testing isn’t just about passing requirements. It’s about building a better, safer, and more reliable product that’s ready for the FDA and the real world.

Start Testing Early. Stay on Track.

Early testing helps catch design issues before they get expensive. It also makes your development process smoother, more efficient, and more compliant with FDA and ISO standards like:

- ISO 13485 for medical device quality management

- ISO 10555 for catheters

- ISO 25539 for stents and vascular implants

- ISO 80369 for Luer connectors

- ISO 7886 for syringes

We help teams design to these standards from day one, so testing becomes a tool, not a barrier.

What We Mean by “Integrated Medical Device Testing”

Here’s how we build testing into every step of device development:

Planning with Standards in Mind

We define your device’s performance goals and create test plans that line up with ISO and FDA expectations. That includes things like burst pressure, tensile strength, and luer connector testing, depending on your device.

Testing in the Right Environment

Our labs are ISO/IEC 17025 accredited and our cleanrooms meet ISO 14644 requirements. That means we can run testing in controlled environments that are ready for submission data and audits.

Custom Test Fixtures

Most devices need more than just standard tests. We build custom fixtures and simulated-use setups to test how your product will really perform in the body.

Real-Time Feedback

As we test, we share results quickly with your engineering team so designs can be adjusted without losing time. This prevents surprises at design freeze or verification.

Submission-Ready Documentation

We don’t just test, we document. All protocols, raw data, and reports are compiled into a format that fits directly into your Design History File (DHF) and regulatory submissions.

Our Medical Device Testing Services

Here are just a few of the test services we offer:

- Catheter Testing (ISO 10555): flow rate, burst, balloon fatigue

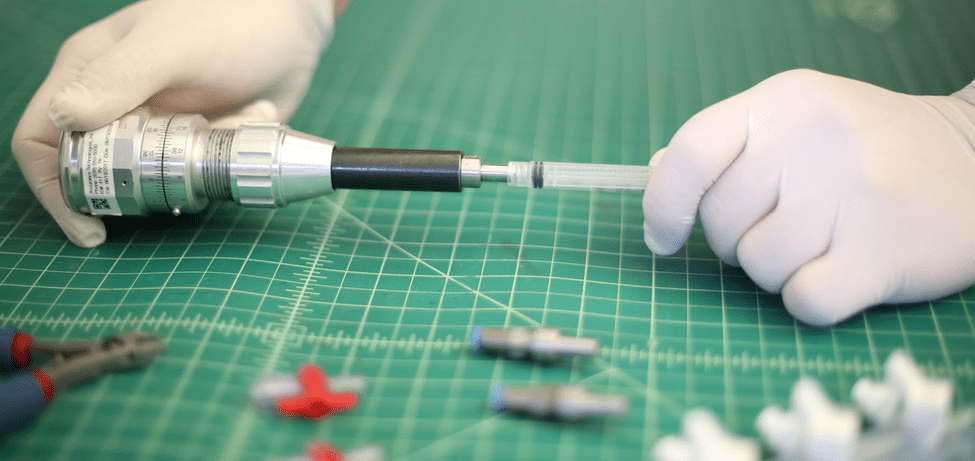

- Luer Testing (ISO 80369): leak, separation force, stress cracking

- Syringe Testing (ISO 7886): plunger force, leak resistance

- Stent & Implant Testing (ISO 25539): fatigue, deployment force, radial strength

- Functional & Mechanical Testing: tensile strength, torque, peel, kink

- Sterilization & Packaging: shelf-life testing, seal strength (ASTM F1980, ISO 11607)

Why Testing Matters

When testing is part of your development, not just an afterthought, you end up with:

- Fewer surprises during verification

- Smoother regulatory submissions

- Devices that are ready for manufacturing and scale

Whether you’re building a catheter, stent, or smart device, our integrated testing approach gives you the confidence to move forward.

Let’s test early. Test often. And test smart.

Want to work with a proven medical device testing partner? Contact Medical Murray today.