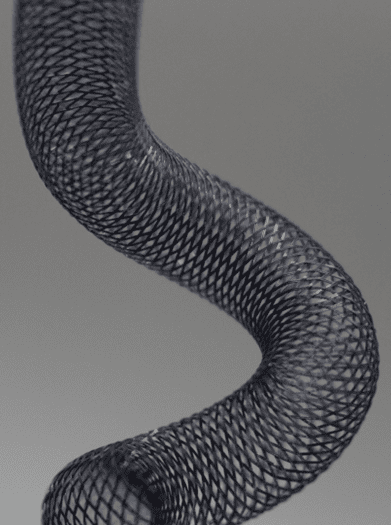

For many next-generation minimally invasive devices, braided catheter shafts are at the heart of performance. The way a catheter bends, rotates, and resists kinking inside the body isn’t random. It’s the result of very deliberate design and manufacturing choices. At Medical Murray, we work with engineers and device developers to fine-tune braiding techniques that help achieve the right balance of flexibility, torque response, and kink resistance.

Why Braiding Matters

Braiding isn’t just reinforcement. It directly shapes how a catheter behaves during a procedure. Different clinical applications require very different performance profiles:

Flexibility

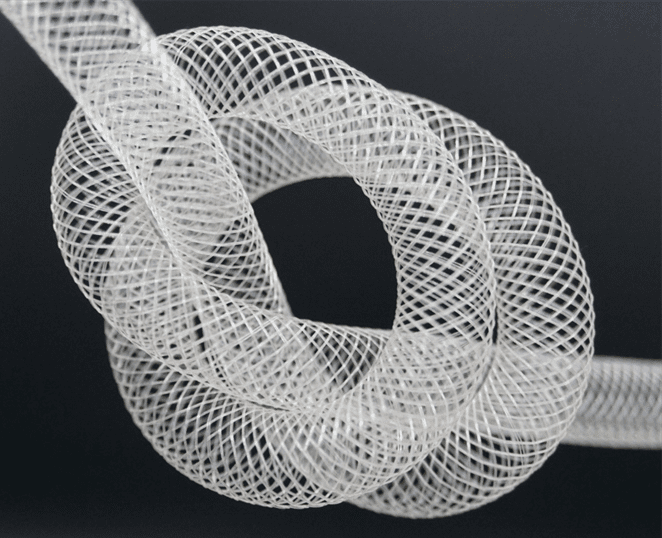

For navigating tortuous anatomy, looser braid structures or thinner wires help the catheter bend more easily without compromising strength.

Torque Response

When the physician twists the proximal end, they need the distal tip to respond predictably. A tighter, more uniform braid improves torque transmission.

Kink Resistance

The braid acts like a structural backbone, helping the catheter maintain its shape when pushed, pulled, or bent inside the body.

The challenge is that optimizing one factor can affect others, which is why setup choices are critical.

How Setup Choices Influence Performance

Small adjustments in braid design can make a big difference in how the device performs:

Wire Diameter & Material

Thinner wires improve flexibility, while thicker wires add push strength and durability. We work with stainless steel, nitinol, and hybrid wire designs depending on the application.

Pick Count (Braid Angle and Braid Density)

Higher pick counts create a stiffer shaft with stronger torque control, while lower pick counts improve trackability and flexibility.

Braid Patterns

A standard one-over-one braid is common, but for advanced applications, we engineer custom patterns that improve pushability and device responsiveness.

Integration with Multi-Layer Shafts

Many modern catheters combine braided reinforcement with multi-durometer extrusions or co-extruded layers to create highly tailored performance profiles.

At Medical Murray, we help our partners select the right combination of these variables early in development, avoiding costly redesigns down the line.

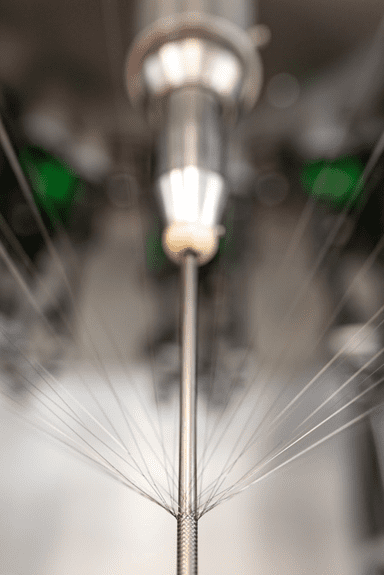

From Prototype to Production

Because we handle both catheter development and manufacturing, we can move quickly from concept to first builds. Our engineers create prototypes with different braid configurations, evaluate their performance, and refine the setup before scaling into production. This iterative approach helps device developers make data-driven decisions without slowing down timelines.

Supporting the Next Generation of Devices

Our braiding expertise supports a wide range of next-generation devices, including:

- High-strength neurovascular microcatheters

- Large-diameter structural heart delivery systems

- Single-use devices designed for robotic-assisted procedures

As minimally invasive procedures become more complex, catheters must deliver better control and reliability, and advanced braiding techniques are central to making that possible. If you’re developing a catheter where flexibility, torque, and kink resistance are critical, our team can help you get the setup right from the start. Contact us to start the conversation.