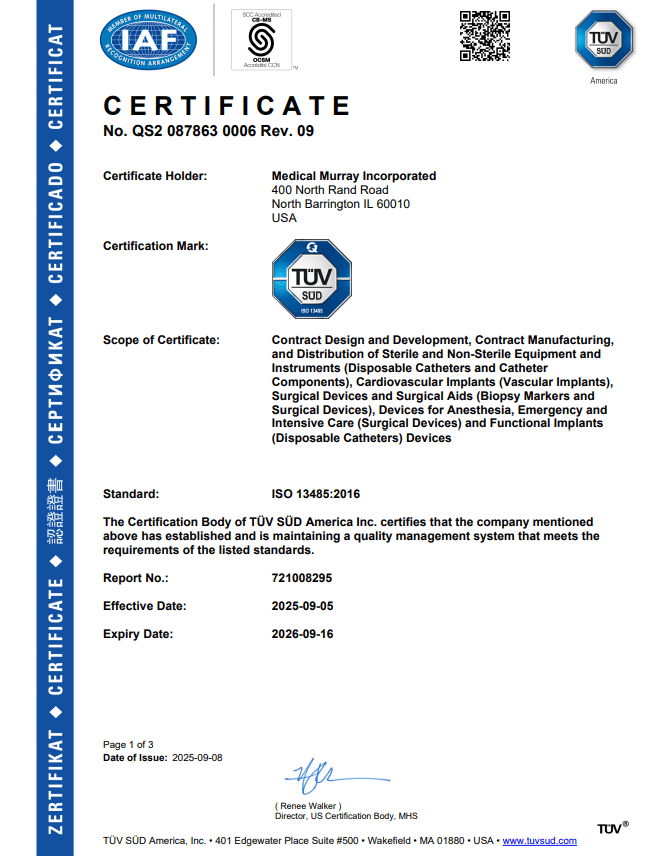

When people hear “ISO 13485 certified,” they often think of it as a stamp of approval or a box to check for audits. But it’s much more than that. ISO 13485 sets the foundation for building medical devices that are safe, consistent, and ready to grow from early prototypes to large-scale manufacturing. At Medical Murray, we don’t just hold ISO 13485 certification, we apply it daily across design controls, risk management, supplier quality, and process validation so your device can move faster with compliance built in.

What is ISO 13485?

It’s the global quality standard for medical devices. It lays out how companies should design, build, and manage devices to ensure patient safety and meet regulatory expectations.

Why it Matters?

ISO 13485 makes sure every catheter, implant, and single-use device is developed with traceability, testing, and risk management built in. That means fewer mistakes, safer products, and smoother paths through FDA or CE approvals.

What it Takes to Get Certified

New companies typically need to:

- Build a quality system with written procedures for design, suppliers, and production.

- Prove design controls (user needs → design inputs → verification/validation → design transfer) and maintain a complete DHF.

- Train teams to procedure.

- Pass an external audit by a notified body or registrar.

This process usually takes 12-18 months and requires significant time, money, and expertise. For many startups, it can delay innovation and eat into funding.

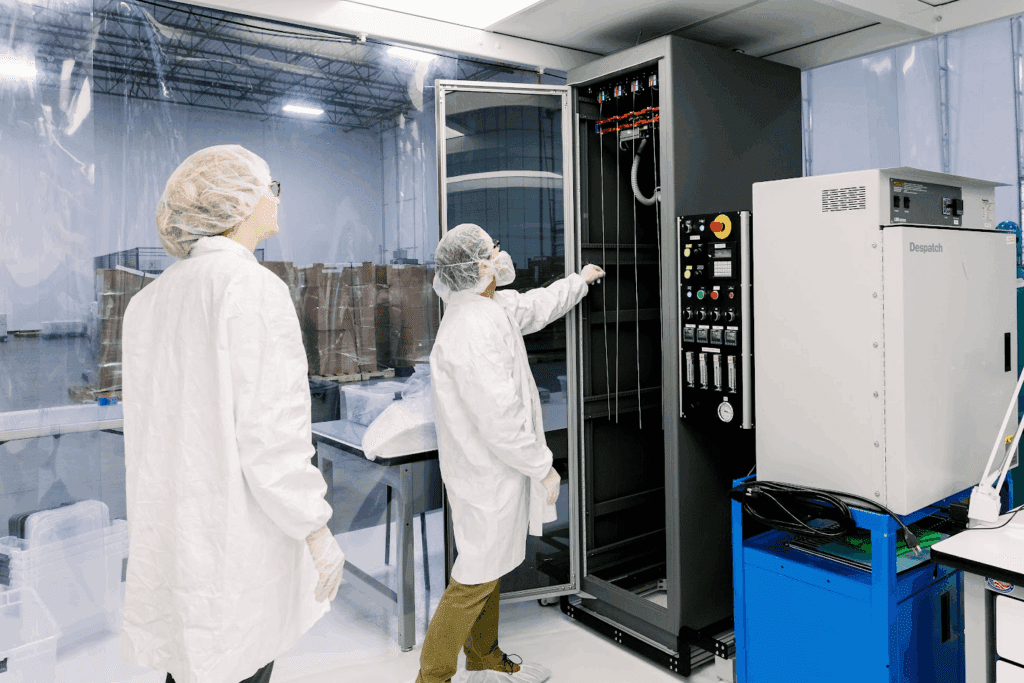

Why Work with a CDMO Like Medical Murray

Leverage a proven, audited quality system so you can focus on the device:

- Faster start: Our ISO 13485 system is in place and ready to support your project today.

- Design controls included: We provide documents needed for the Design History File and keep them development compliant so you can focus on the device itself.

- Scales with you: Whether you’re making first prototypes or preparing for manufacturing, our processes are built to grow with your project.

- Regulatory confidence: With ISO 13485 as our baseline, your device is aligned with FDA and global expectations from day one.

ISO 13485 isn’t just paperwork. It’s the baseline for building safe devices and scaling them into successful products. Trying to achieve it on your own takes time and money you may not have to spare. At Medical Murray, the system is already in place. By working with us, you gain a partner who brings both compliance and experience, giving your device the best chance to reach patients safely and successfully.

Want to learn how our ISO 13485-certified team can support your project? Let’s talk.