Women’s health has been underrepresented in medtech for far too long.

Not because the clinical needs are small, but because they have often been treated as niche.

We do not see it that way.

At Medical Murray, women’s health is not a side category or a temporary focus. It is a critical and growing area of medical device innovation, and one where engineering precision, manufacturing ownership, and long-term scalability matter just as much as the original concept.

More than half of our team is female, including a majority of our engineers, business development professionals, and manufacturing workforce. That perspective is not symbolic. It shapes how we collaborate, how we evaluate risk, and how seriously we take ownership of outcomes across the product lifecycle.

Technical capability matters. Passion does too.

And when you are developing interventional women’s health and FemTech medical devices, both are required.

Women’s health innovation is moving fast. Across breast health, gynecology, pelvic health, and gynecologic oncology, and increasingly across chronic diseases that disproportionately affect women, teams are developing interventional devices that are thoughtful, ambitious, and long overdue.

But great ideas do not become real medical devices on their own.

In interventional women’s health, success is often decided by:

- How early manufacturing enters the conversation

- How precisely a device is built

- Whether the people building it take real responsibility for what happens after the prototype stage

That is where many promising programs either sharpen or stall.

Women’s Health Is Not a Niche Market

Women’s health and FemTech are sometimes described as niche categories. From a development and manufacturing perspective, that framing does not hold up.

Women’s health medical devices include far more than products used only in OB-GYN procedures. They also include interventional tools and implants used to diagnose and treat chronic conditions that affect women differently or more often than men. These devices are just as complex, just as regulated, and just as critical as any other interventional medical device.

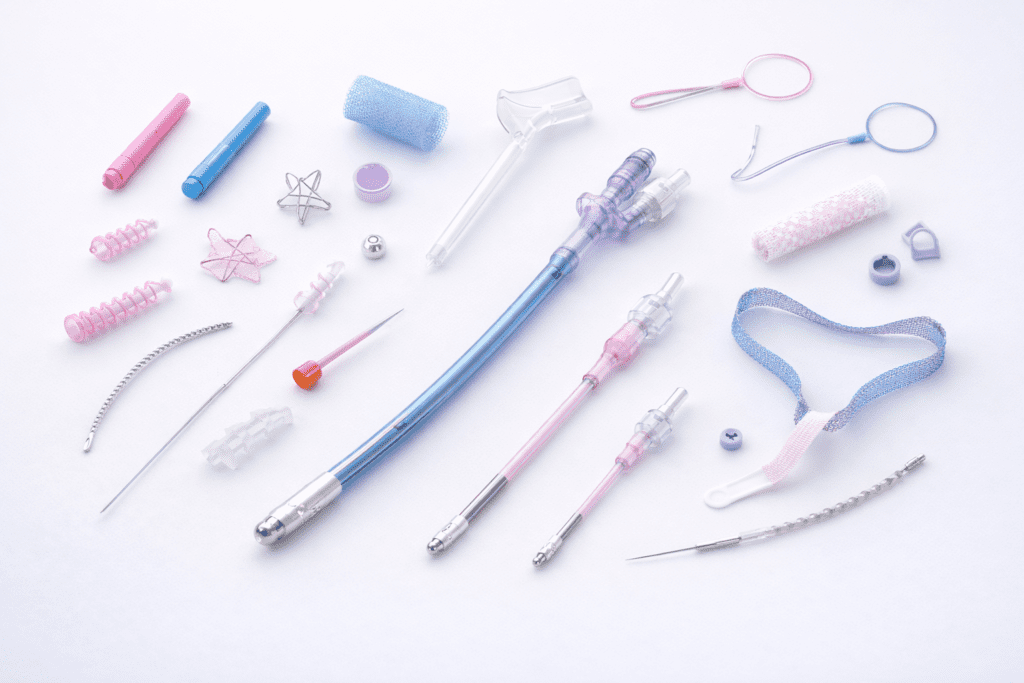

Catheters, implants, meshes, anchors, and bioabsorbable components used in women’s health require the same rigor, focus, and discipline as any Class II or Class III device program.

Different Devices. The Same Core Challenges.

A breast biopsy marker and a pelvic health implant may look unrelated. They are used in different procedures and treat different conditions.

But when you look closely, the building blocks are often the same:

- Implantable or semi-implantable components

- Catheters and delivery systems

- Polymers, braids, meshes, and other soft materials

- Tight tolerances that directly affect performance

- The need to scale production without redesigning the product

Because of this, many women’s health and FemTech programs face the same engineering and manufacturing challenges regardless of indication.

Size Matters More Than It Gets Credit For

One reality that shows up often in women’s health is device size.

Historically, many general use medical devices have been designed around larger anatomies. In some cases, this has led clinicians to adapt pediatric devices for adult women simply because they are smaller and easier to use.

That workaround highlights a real need for well designed, small profile devices built specifically for women.

Designing and manufacturing these devices is not simple. Smaller profiles often mean tighter tolerances, more complex assemblies, greater sensitivity to material behavior, and less room for error.

This is an area where experience with precise, small form interventional devices truly matters.

These Devices Do Not Forgive Mistakes

Interventional women’s health devices leave very little margin for error.

Common and foreseeable challenges include:

- Materials that behave differently over time

- Small tolerance shifts that impact performance

- Delivery systems that are harder to manufacture than expected

- Scale issues that force late design changes

These problems rarely come from bad ideas. They show up later, usually because manufacturing decisions were made too late or without the full product lifecycle in mind.

Manufacturing Decisions Happen Earlier Than Most Teams Expect

In women’s health device development, early design choices quietly shape long term outcomes.

Material selection.

Braid architecture.

Polymer processing.

Assembly methods.

Inspection strategy.

These decisions often feel small early on, but they are the ones that define the program later.

They determine whether a device can scale reliably, how consistent it will be in production, how smooth the regulatory path will be, and whether costs remain predictable over time.

The right manufacturing partner helps teams make these decisions early, intentionally, and with long term production in mind.

Built for the Real World

Medical Murray has spent decades developing and manufacturing complex interventional devices for women’s health, from early feasibility builds through long running commercial production.

That work includes breast biopsy markers, OB-GYN and pelvic health devices, mesh systems, anchors, textile structures, bioabsorbable components, cytology products, and other small profile interventional devices used across women’s health indications.

What we have learned over time is consistent and practical:

devices designed with manufacturing ownership early move faster, scale more cleanly, and last longer.

The transition from prototype to production is where many women’s health devices either gain momentum or lose it.

The Delivery System Matters

In many interventional women’s health devices, the implant is only half the system.

Catheters, introducers, and deployment mechanisms often determine ease of use for clinicians, procedure time, physician confidence, and real world adoption.

Strong implant designs can be slowed by delivery systems that were not designed with the same level of care. When both are developed together, programs move forward with fewer surprises.

Why We Are Personally Invested in Women’s Health

We have already shared that women’s health matters to us. What is important is why that matters in practice.

Women’s health has historically received less attention and investment than it deserves, especially on the manufacturing side. We believe that starts to change when teams bring not just technical expertise, but real commitment to the work and the patients it serves.

At Medical Murray, that commitment is reflected in our team and in how we operate. It influences how we think about risk, how closely we work with customers, and how much ownership we take over long term outcomes.

Not because it sounds good.

Because it is how we choose to work.

Turning Women’s Health Innovation into Lasting Impact

Great ideas are where women’s health and FemTech innovation begin.

The right manufacturing partner helps turn those ideas into devices that are safe, effective, and built to last, from early development through long term production.

As women’s health innovation continues to grow, we are excited to support teams building interventional devices across breast, gynecologic, pelvic health, and chronic women’s health conditions, with the focus, skill, and care these products deserve.