Blog

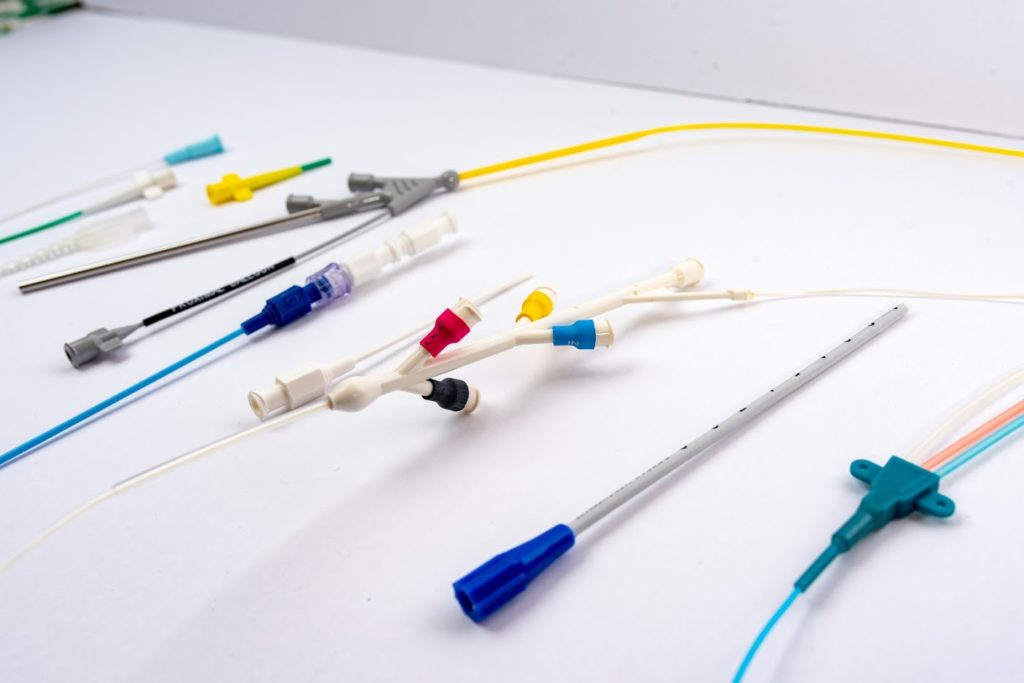

Sensor Integration for Catheters: Boosting Diagnostic and Treatment Capabilities

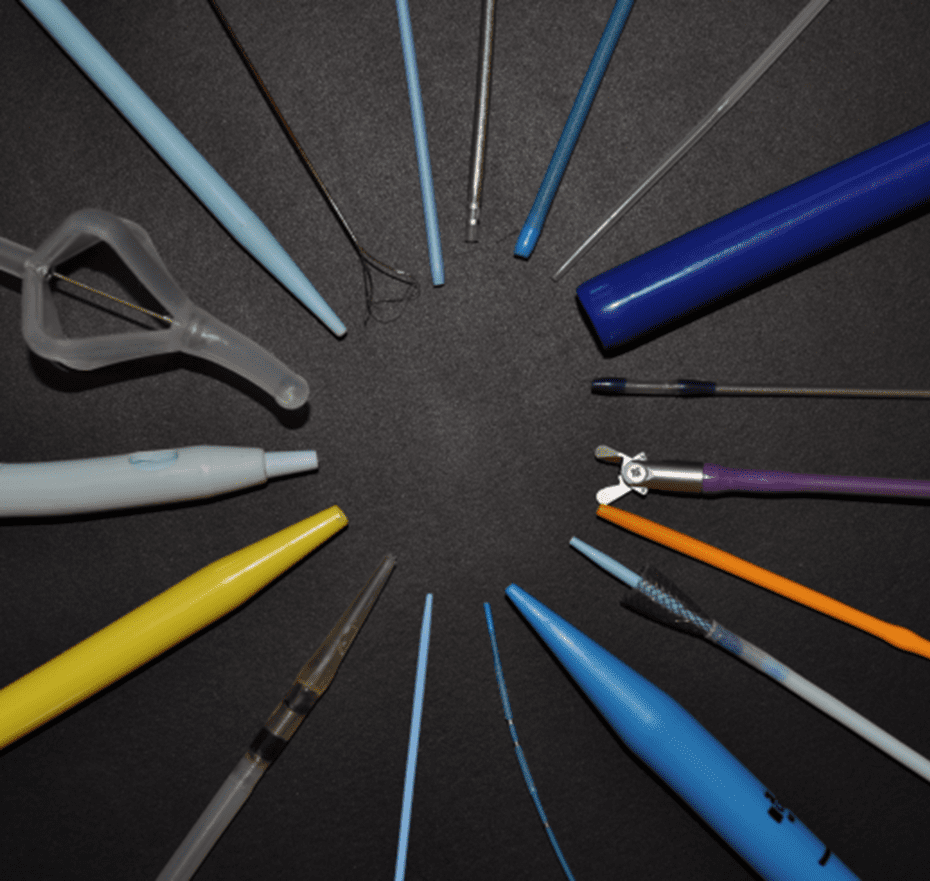

The medical field is advancing rapidly, with new technologies making it possible to diagnose and treat patients more precisely. One of the most exciting developments is integrating sensors into catheters, which has greatly improved both diagnosis and therapy. At Medical Murray, we’re leading the way in this innovation, using our expertise to develop advanced catheters…

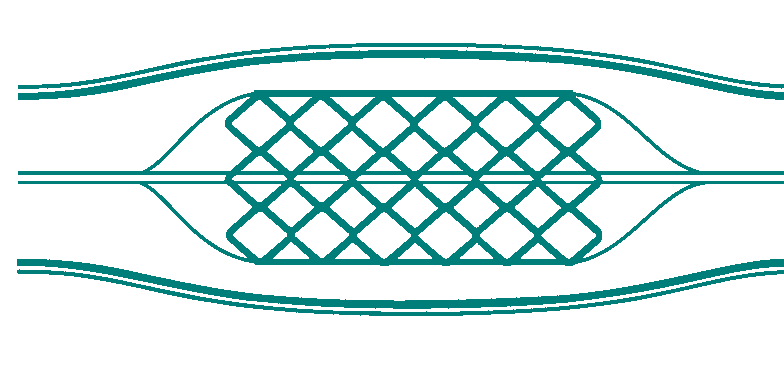

Read MoreManufacturing Transcatheter Implants: Ensuring Consistency and Quality

At Medical Murray, we know that developing a great transcatheter implant is only the first step. Once the design and materials are finalized, the next big challenge is manufacturing the device to meet the specifications required for safe and effective use. This is especially true for complex devices like covered stents and frames. Here’s what…

Read MoreChoosing the Right Manufacturer for Your Class III Medical Device

When developing a Class III medical device, finding the right Contract Development and Manufacturing Organization (CDMO) is critical. These high-risk devices, such as implants and complex catheters, require precision, expertise, and full regulatory compliance. With so much at stake, it’s important to ask the right questions when selecting a partner to help you navigate medical…

Read MoreThe Role of Single-Use Devices in Robotic Surgery: How Medical Murray Can Help

As robotic-assisted surgery continues to evolve modern healthcare, the demand for precision-engineered single-use devices is on the rise. Medical Murray’s expertise in creating complex catheters and implants uniquely positions us to support the growing need for high-quality, single-use devices essential to robotic surgical systems. The Impact of Robotic-Assisted Surgery Robotic surgical systems have redefined the…

Read MoreImproving Radiopacity in Complex Catheters and Implants

In medical devices, visibility is essential for performing safe and effective procedures. Guiding and monitoring complex catheters and implants without adequate imaging can pose significant challenges and risks. Medical devices with greater radiopacity are much easier for practitioners to precisely place and monitor. They’re more visible in imaging, which can make all the difference in…

Read MoreePTFE: A Game-Changer for Medical Device Manufacturers

Transforming the Future of Medical Devices with ePTFE At Medical Murray, we’re pioneering the use of expanded polytetrafluoroethylene (ePTFE) in medical device manufacturing, particularly in complex catheters, implants, and single-use devices. ePTFE plays a vital role in heart valve engineering, stent graft applications, and other innovative heart implants, shaping the exciting future of medical technology.…

Read MoreEnsuring Safety and Sterility in Medical Device Manufacturing: The Importance of Cleanrooms and Bioburden Management

In medical device manufacturing, particularly for high-risk devices like class III implants, maintaining ultra-clean production environments is critical to ensuring product safety and sterility. Managing bioburden – the presence of microorganisms on a product before sterilization – is essential to clean, safe manufacturing practices. Let’s explore the significance of cleanrooms and bioburden management in maintaining…

Read MoreBalancing Budget and Quality in Class III Catheter and Implant Manufacturing

A Roadmap to Quality and Cost-Efficiency In the intricate and highly specialized sector of Class III catheter and implant manufacturing, achieving a synergy between cost-efficiency and quality is a critical goal. As a dedicated Contract Development and Manufacturing Organization (CDMO) for Class III medical devices, our mission is centered around the integration of cost-conscious strategies…

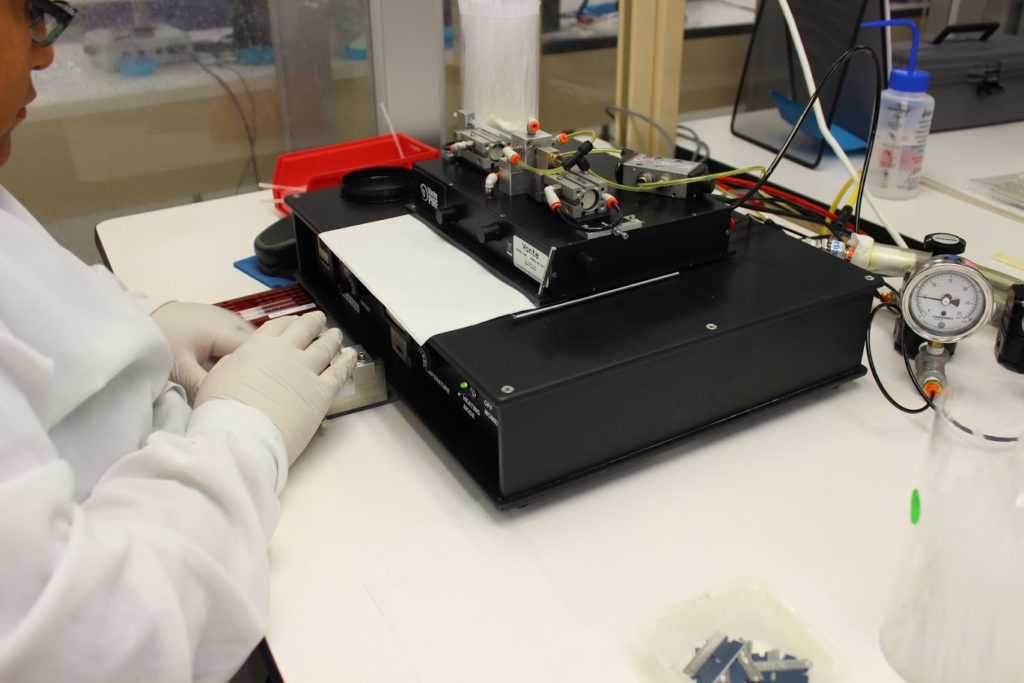

Read MoreThe Importance of Quality Control in Medical Device Manufacturing and Development

One of the most important aspects of ensuring the quality of medical devices is quality control (QC). Medical device quality control is critical to patient well-being and peace of mind.Working with an ISO 13485 certified contract manufacturer like Medical Murray can help put your customers at ease, certain that they’re using a safe, rigorously tested…

Read MoreHow Medical Murray Designs and Forms Catheter Tips

Catheter tips are one of the most important components of a catheter. The tip guides the catheter through the body and toward the target area. The shape, size, and material of a catheter tip can have a significant impact on a medical device’s performance and overall outcome for the patient. This is what makes creating…

Read More