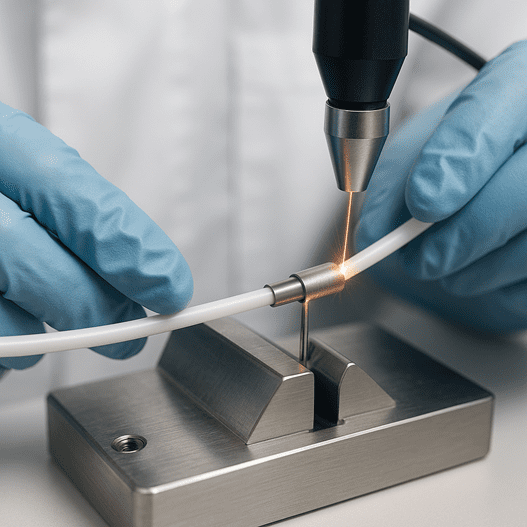

Laser welding uses a hair-thin, high-intensity light beam to join materials with micron-scale precision. By confining all the heat to a microscopic interaction zone, known as the heat-affected zone (HAZ), the process briefly melts the workpiece before it solidifies almost instantly. This tight thermal footprint (often under 50 µm) keeps nearby plastics, sensors, and coatings intact, making laser welding a go-to method for today’s most demanding medical device assemblies.

Laser Welding Applications in Catheters

Pull-wire-to-band welds: A steerable catheter bends when a thin wire (usually stainless steel or nitinol) is pulled inside the shaft. The wire must be welded to a tiny metal band that sits near the catheter tip. A few laser pulses, each lasting only 1–2 milliseconds, lock the wire to the band. These sub-assemblies are commonly tensile tested before being shipped.

Radiopaque marker-band spot welding: Surgeons rely on gold or platinum-iridium rings to see a catheter’s position under X-ray. Laser spot-welding fixes these bands onto a stainless hypotube so they never slip.

Multi-tube seam welding: To create a smooth stiffness taper at the distal end, we seam-weld a thin-wall hypotube onto a thicker section, sealing the joint without introducing any steps or gaps.

Why laser welding beats other joining methods inside catheters

- Minimal HAZ: Keeps polymers, adhesives, and sensors safe.

- Minimal consumables: Uses only inert gas shielding, no filler rods or flux, so there’s no debris in the sterile path.

- Fast cycle time: The same program runs from one-off prototypes to full-scale production lots.

Design tips for laser welding catheters

| Tip | Why it Matters |

| Leave a clear “weld window.” Strip back jackets or shrink-tube so the laser has line-of-sight. | The beam can’t melt what it can’t see. |

| Hold parts within ±10 µm. Use precision nests or vision guidance. | Consistent spot overlap = predictable strength. |

| Plan pull testing. Leave enough length of wire exposed. | QA can test every catheter without destroying it. |

| Match metals when possible. Stainless-to-stainless is easier than stainless-to-nitinol. | Fewer metallurgy headaches. |

Laser Welding Nitinol: Hero & Headache

Nitinol’s shape-memory makes it ideal for minimally invasive tools, but it’s sensitive to heat. Excessive dwell time can form brittle nickel-rich phases that crack under flexing. To protect nitinol joints, we:

- Use ultra-short, low-energy laser pulses

- Flood the weld zone with argon gas to prevent oxidation

- Apply a gentle post-weld heat-relief cycle when designs allow

Studies show that careful pulse shaping and gas shielding preserve nitinol’s memory properties and dramatically reduce embrittlement.

Beyond Catheters: Techniques for Medical Device Laser Welding

| Laser Technique | Example | Benefit |

| Spot & seam welding (metals) | Sealing pacemaker cans | Hermetic (airtight) joints keep moisture out of electronics. |

| Through-transmission plastic welding | Drug-delivery pods, test cartridges | Bonds two plastic halves without screws or glue, no particles, no mess. |

| Oscillated bevel welding | Titanium implant housings | Fix complex curves with uniform strength. |

Universal upsides

- Micron-scale accuracy: Beam spots under 50 µm join foils, wires, even sensor pads that soldering would destroy.

- High Speed: Up to 5x faster than other welding and there’s no electrode to wear out.

- Clean-room friendly: Non-contact process makes almost zero spatter.

- Easy to qualify: Welders follow ISO 14732, the global rulebook for automatic and mechanized welding.

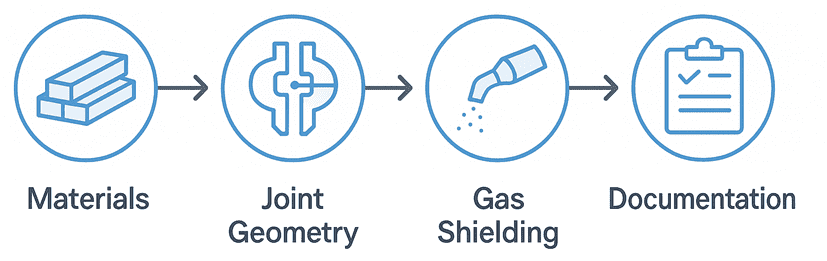

Design checklist for any laser-welded device

- Pick compatible materials. Similar alloys fuse easiest; dissimilar pairs may need a thin “buffer” layer.

- Ensure line-of-sight. Butt joints leave no trapped gas; lap joints might.

- Shield with inert gas. Argon (or argon-helium) keeps hot metal from oxidizing.

- Document every parameter. Log power, speed, and test results by lot number.

Choosing your laser: Nd:YAG vs. fiber

- Pulsed Nd:YAG: Great all-rounder; flexible pulse shaping for odd alloys.

- Fiber laser: Higher power density and lower maintenance for long production runs.

Medical Murray: Experts in Laser Welding Medical Devices

Our Illinois clean rooms have lasers with real-time power feedback. Need a weld for your next-gen steerable catheter? Or a leak-tight titanium housing that guards delicate sensors? Send us your STEP file or a physical sample, and we’ll map out a process including prototypes, verification and validation, and a path to full scale production. Request a quote today to get started.