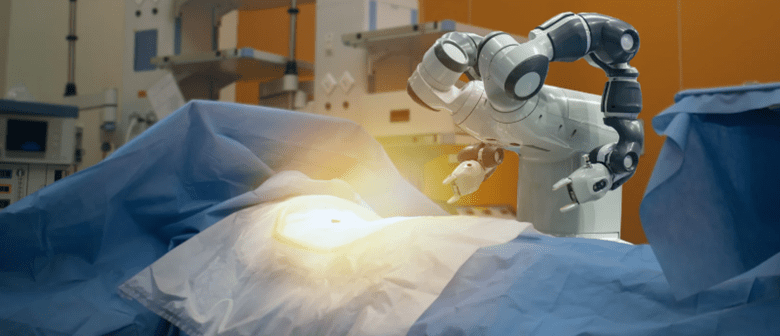

Robotic-assisted surgery has changed what is possible in the operating room. These systems give surgeons better control, steadier hands, and access to areas of the body that are hard to reach. The technology is impressive and deserves the attention it gets.

But even the best robot-assisted surgery system depends on the tools that do the work inside the body.

At Medical Murray, we are most passionate about designing and manufacturing surgery tools and medical devices. We create the catheters, delivery systems, and single-use scopes that connect the robotic system to the patient and carry out essential treatments. These devices are the bridge between robotic precision and patient care. They are what allow the robotic system to successfully administer treatments and perform procedures.

How Robotic-Controlled Devices Are Different

Catheters and scopes designed for robotic systems are not just regular tools with a new label. They need to work hand-in-hand with the robot. They must be designed specifically for how the robot moves, connects, and controls the device.

Here are a few differences between robotic-assisted surgery tools and regular surgical devices.

They Connect Directly to the Robotic-assisted Surgery System

Robotic devices often need special connectors or docking features that allow the system to control the tool. The robot may be advancing, steering, or deploying the device. If so, it needs a secure and reliable way to take over that control.

They Include Sensors for Feedback

The robot relies on real-time feedback to guide its movements. Many robotic-controlled catheters and scopes include sensors that measure things like force, position, or pressure. These sensors help the system make precise and safe adjustments during the procedure.

They Are Designed Beyond the Limits of Human Hands

Because the robot, not a person, moves the device, the design is not limited by what a human hand can grip or control. This allows for more flexible, more advanced designs like multi-directional steering or very fine movements that would be hard or impossible to do by hand.

They Must Meet Higher Demands for Precision and Performance

Robotic systems expect a level of consistency and accuracy that can be much tighter than what is required for hand-held tools. These devices still need to meet the same safety, sterilization, and material standards, but they must also perform perfectly with the robot every time.

How We Support Robotic-Assisted Surgery Device Development

At Medical Murray, we bring 30 years of experience making complex catheters, delivery systems, and implants. We are already supporting projects where these types of devices are being used with robotic systems.

Our team helps design and manufacture:

- Steerable and deflectable catheters that can be controlled by the robot

- Delivery systems for implants, stents, or valves that require precise robotic movement

- Single-use scopes and sheaths made for robotic articulation and imaging

- Devices with sensors built into the system to give the robot feedback on force, position, or pressure

We can help at any stage, whether you need quick-turn prototypes, testing services, or full-scale manufacturing in an ISO 13485 environment.

Surgery Tools Matter as Much as the Robot

The future of robotic-assisted surgery relies on both the system and the tools working together. The robot provides precision and control. The devices bring that precision to the patient. Both are critical for success.

At Medical Murray, we are proud to focus on the devices that bring robotic precision directly to the patient.

Contact Medical Murray

If you are working on robotic-controlled catheters, delivery systems, or scopes, we would love to hear about your project and see how we can help.

#MedicalMurray #RoboticSurgery #Catheters #ImplantDelivery #SingleUseDevices #MedTech