Blog

Avoiding Common Pitfalls in Medical Device Testing

How to De-risk Your Path to Regulatory Approval and Market Success When it comes to medical devices, testing isn’t just a checkbox. It’s a critical step that determines safety, performance, and your path to regulatory approval and commercialization. At Medical Murray, we’ve seen firsthand how missteps in testing can cause major delays, regulatory pushback, and…

Read MoreHow Medical Murray Partners on Medical Device Iteration Post-Launch

Launching a medical device is just the beginning. At Medical Murray, we understand that once a product is in the hands of clinicians, new ideas for improvement often follow. That’s why we partner closely with our customers after launch to support design refinements, address real-world feedback, and enable smooth, compliant updates to commercialized devices. Why…

Read MoreWhy More Medtech Companies Are Moving Manufacturing to the U.S.

If the U.S. is a big part of your growth plan, where you make your device matters. Whether you’re developing robotic-assisted catheters, single-use scopes, or ablation catheters like pulse field ablation, many medtech companies are realizing it’s smarter and safer to manufacture closer to their customers. Tariffs, shipping delays, and regulatory headaches are just a…

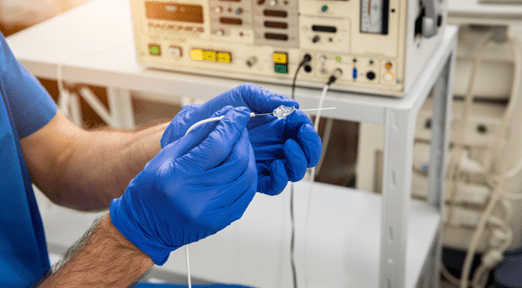

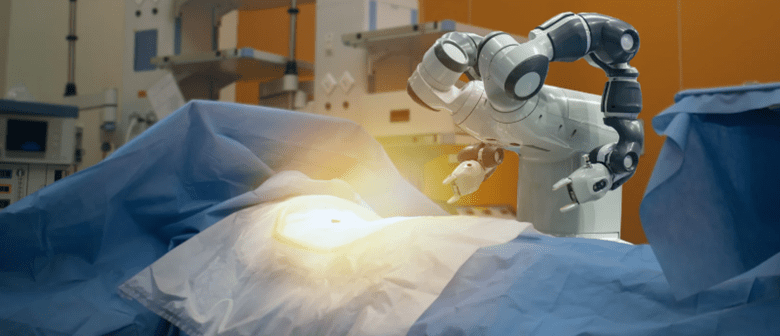

Read MoreRobot-Assisted Surgery Depends on High-quality Tools

Robotic-assisted surgery has changed what is possible in the operating room. These systems give surgeons better control, steadier hands, and access to areas of the body that are hard to reach. The technology is impressive and deserves the attention it gets. But even the best robot-assisted surgery system depends on the tools that do the…

Read MoreWhy Medical Device Startups Thrive with Medical Murray

At Medical Murray, we don’t just “work with” startups, we love startups. We’ve built our name on transforming early-stage concepts into breakthrough medical devices, particularly with complex catheters and transcatheter implants. Our entrepreneurial spirit fuels a close-knit, collaborative culture where new ideas flourish, and we move quickly from concepts to prototypes, and eventually to pilot…

Read MoreISO 10555 Testing: What Catheter Developers Need to Know

If you are working on an intravascular catheter, there is one standard you need to be familiar with: ISO 10555. This international standard sets the bar for testing catheter performance and plays a key role in design verification and regulatory approval. At Medical Murray, we design and manufacture advanced catheters every day. Our testing capabilities…

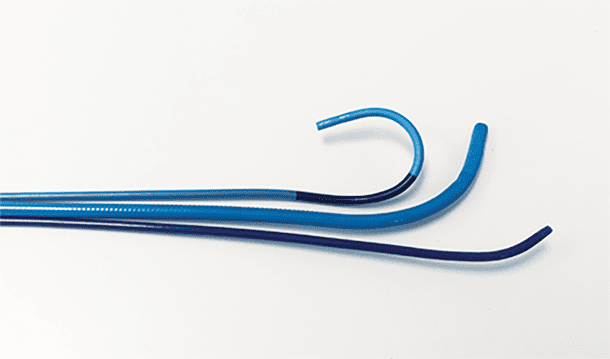

Read MoreSteerable and Deflectable Catheters: How They Work

In the world of minimally invasive medicine, precision is everything. Whether it’s a heart procedure, a delicate neurovascular intervention, or placing a stent in a complicated artery, the ability to navigate the body with pinpoint accuracy is crucial. Steerable and deflectable catheters are game-changing technologies that have drastically improved the way doctors perform these…

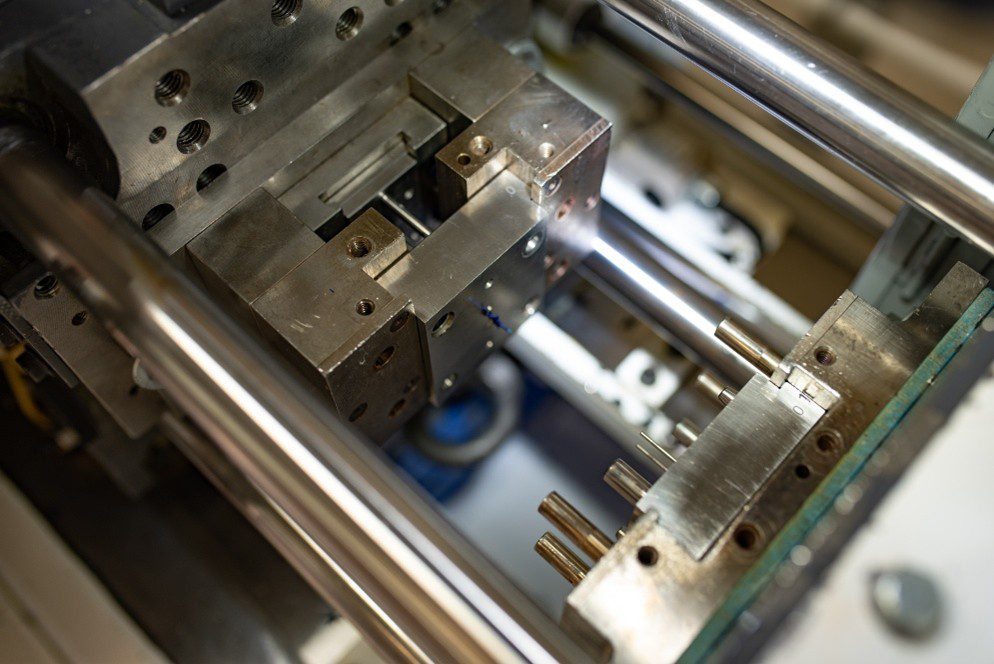

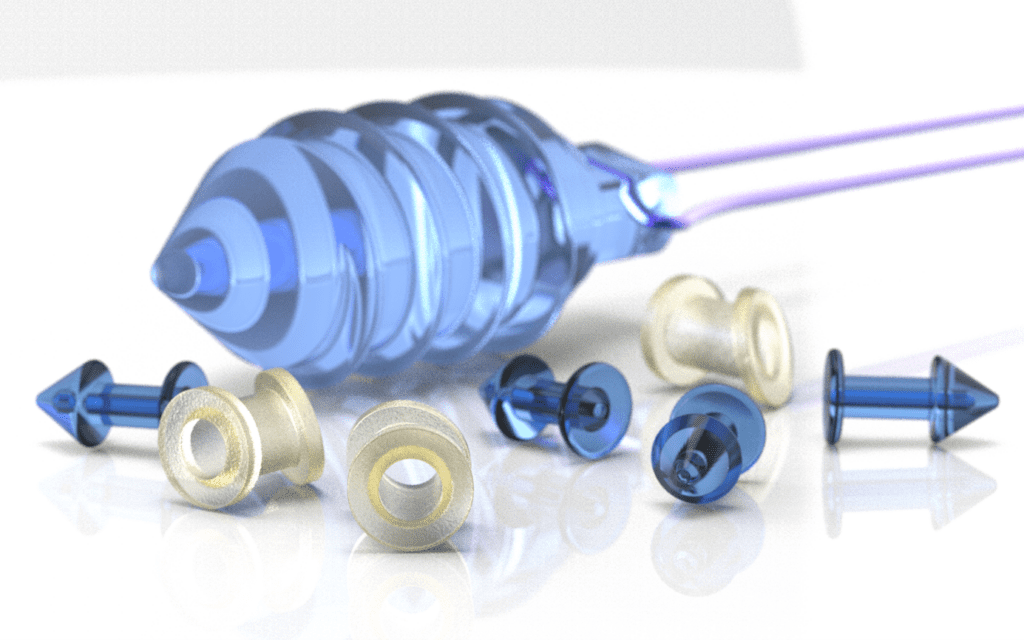

Read MoreMicro Insert Molding for Implants: Smaller, Smarter, Stronger

Implantable medical devices are getting smaller, smarter, and more complex. Whether it’s neuromodulation implants, cardiac rhythm management (CRM) devices, or transcatheter implants and their delivery systems, precision is everything. That’s where micro insert molding is ideal for integrating miniature components into high-performance polymer implants. This advanced manufacturing technique enables the seamless encapsulation of tiny metal,…

Read MoreWhat It Takes to Develop and Manufacture Complex Catheters

Complex catheters are more than just flexible tubes. They are highly engineered tools designed to navigate the body’s most delicate pathways, deliver therapy, capture images, or deploy life-saving implants. Each section, from the soft tip to the handle, has a critical job to do. Getting it right demands a precise combination of expertise, equipment, and…

Read MoreNitinol in Medical Devices: Revolutionizing Catheter and Implant Manufacturing

Ever wonder how medical device engineers transform a simple wire into a lifesaving, high-tech catheter or stent? The answer often lies in Nitinol, a nickel-titanium alloy that is loved for its shape memory and superelastic properties. In other words, bend it, flex it, even tie it in knots, and Nitinol will bounce back to its…

Read More