Blog

What is ePTFE?

ePTFE, or expanded polytetrafluoroethylene, is a highly durable and biocompatible material that is often used in medical procedures where longevity, biocompatibility and controlled porosity is desired. ePTFE is made from the same polymer as Teflon but expanded to create a porous structure. ePTFE can be processed with structural orientation to be very thin while maintaining…

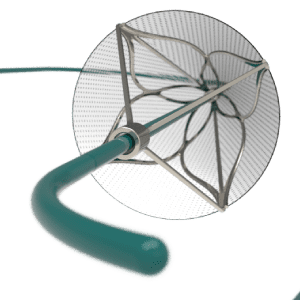

Read MoreDevelopment of Transcatheter Implant Systems

Transcatheter implants are a type of medical device that can be delivered within the body through a catheter designed to access the anatomy through the smallest opening possible. There are many types of implants that can be delivered through a catheter including: Transcatheter implants have revolutionized the way certain medical conditions are treated by providing…

Read More4 Ways to Speed Up Medical Device Development

The medical device design and development process is complex and time-consuming. It demands a wide range of expertise in engineering, regulatory compliance, and clinical testing. However, there are several strategies that companies can use to bring safe and effective products to market more quickly. Know the Needs Your Medical Device Serves It’s critical to clearly…

Read More3 Reasons Why You Should Manufacture Your Medical Device in the United States

Choosing a manufacturing partner that is the right fit for your product and business is critical. Manufacturing in the United States might be best if your product…

Read MoreManaging Expectations for a Medical Device Manufacturing Transfer

Have you recently received CE approval, IDE approval or FDA approval? If yes, congratulations! The road to demonstrate product performance and address all regulatory requirements can be difficult.

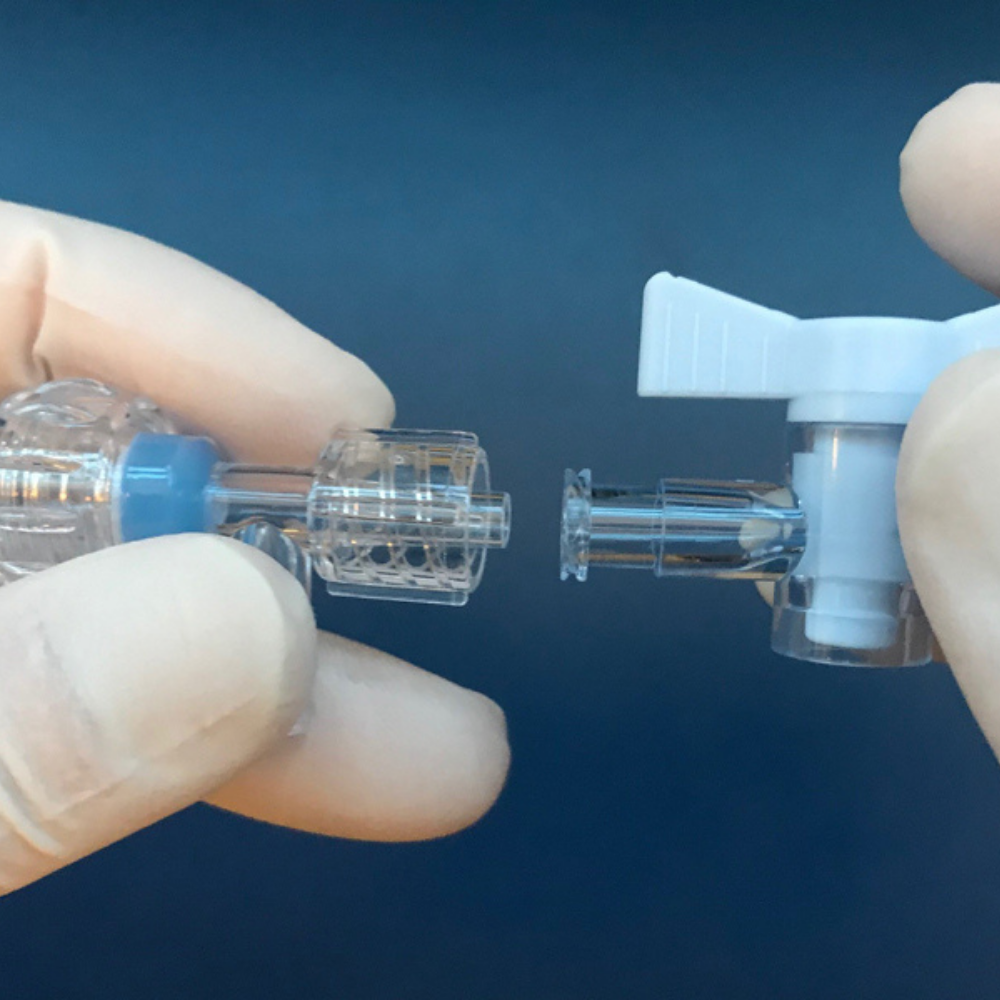

Read MoreBenefits and Risks of Luer Connector Compliance Testing

Patients in healthcare settings often receive medication and medical therapies through a variety of devices or delivery systems. These systems include syringes, catheters and tubing sets that connect to each other.

Read MoreEnhancing Catheter Steerability and Deflection

Steerable catheters and deflectable catheters require advanced design and development practices. New catheter navigation technologies using magnets or electricity could be used.

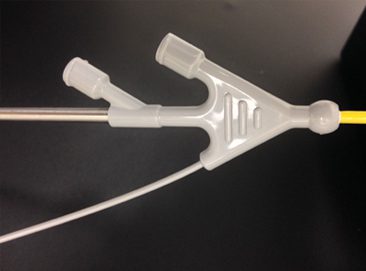

Read MoreCollaboration in Catheters

Medical Murray has developed innovative catheter technologies by working with its customers and down its supply chain. The company first opened its doors on April Fool’s day 20 years ago, but its success has been anything but a joke. In fact, it’s the result of a collaborative effort. As a leading supplier of complete catheter systems for…

Read MoreLuer Testing Services to ISO 80369 Standards

Medical Murray, a leading device development and contract manufacturing company with ISO 13485 certification and FDA registration, provides comprehensive testing services for Luers including ISO (part 1 and 2) and ISO 80369 standards.

Read MoreMolding Services for Components and Devices

Medical Murray, a device development and contract manufacturing company with ISO 13485 certification and FDA registration, provides complex catheter design and unique insert molding advantages for devices made from a wide range of materials, both thermoplastic and silicone rubber. Medical Murray’s “nano-molding” services refer to parts in a cubic millimeter range (1/10th the size of micro-molded parts), which provides the ability to mold components as small as .1 cubic millimeter.

Read More