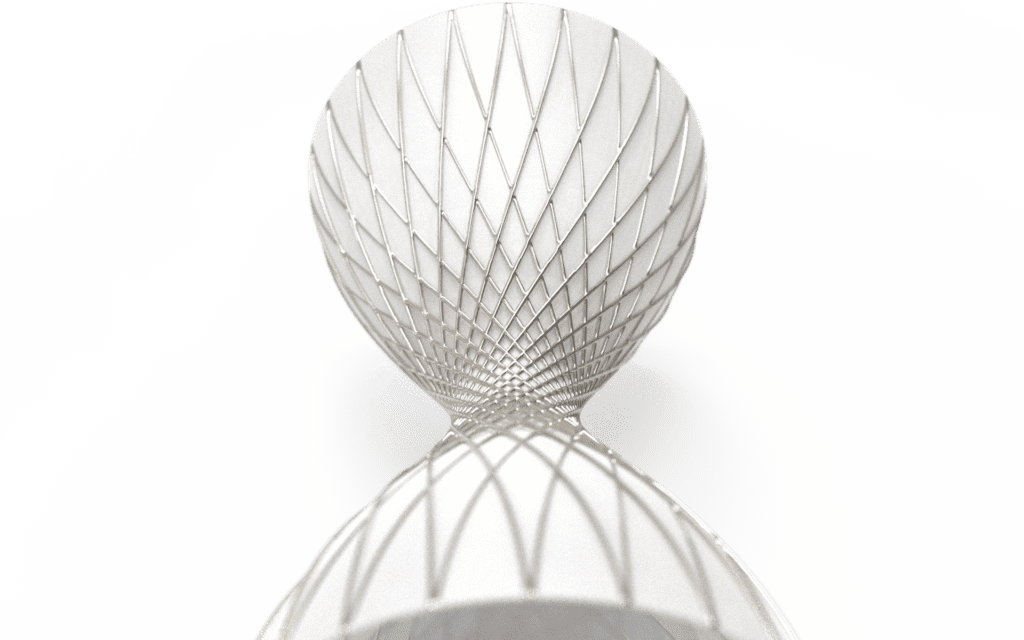

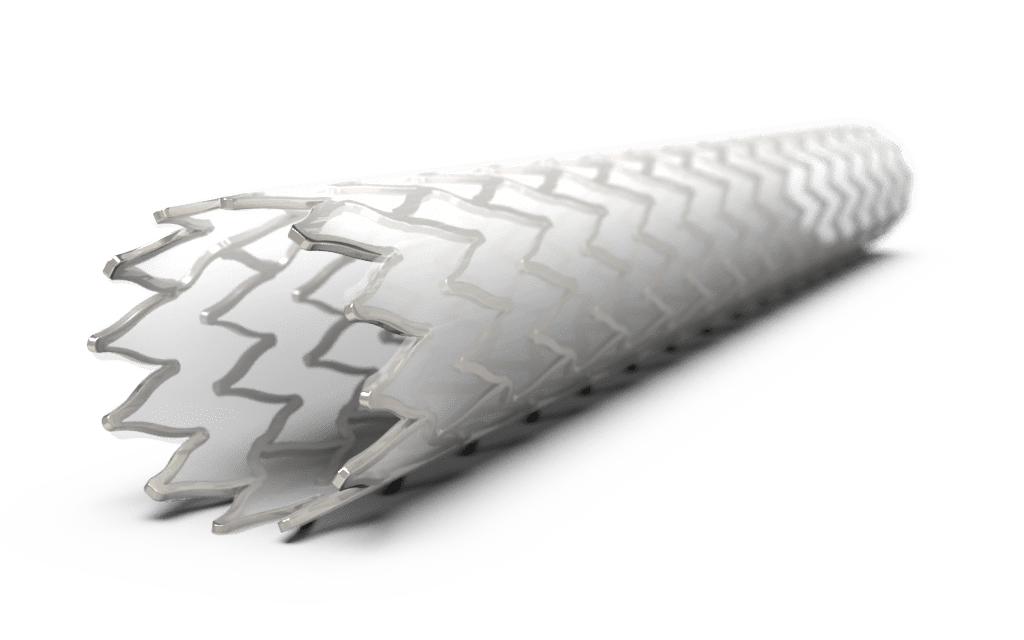

At Medical Murray, we’re passionate about driving innovation in medical device manufacturing. One material that continues to inspire us and transform the industry is expanded polytetrafluoroethylene (ePTFE). Known for its unmatched biocompatibility, durability, and flexibility, ePTFE is at the core of cutting-edge solutions for vascular, gastrointestinal, and surgical applications. Whether we’re crafting covered stent grafts or precision-engineered patches, ePTFE is helping us deliver life-changing devices.

What Makes EPTFE Unique?

If you’re in the medtech world, you know that materials matter. ePTFE offers a unique combination of features that make it a game-changer for medical devices:

- Ultra-Thin, Ultra-Strong: Engineered to be thin without sacrificing strength, ePTFE allows for smaller profiles in devices like stent grafts, making it easier to navigate challenging vascular pathways.

- Incredible Flexibility: Its ability to conform to complex anatomical structures improves sealing, reduces risks like endoleaks, and simplifies device adjustments.

- Safe for Patients: With its exceptional biocompatibility, ePTFE minimizes inflammation, immune response, and rejection risks—essential for long-term implants.

- Built to Last: ePTFE doesn’t degrade over time, ensuring durable performance and reducing the need for replacements.

How Medical Murray Optimizes ePTFE Stent Grafts

Designing with ePTFE requires precision and expertise. At Medical Murray, we specialize in turning this versatile material into high-performing solutions for complex medical devices. Here’s how we do it:

- Customizing Porosity: We fine-tune the balance between permeability and strength, promoting optimal tissue integration.

- Perfecting Stent Integration: ePTFE is seamlessly combined with nitinol or stainless steel frameworks to create secure and reliable devices.

- Ensuring Patient Safety: We optimize sterilization processes while preserving material integrity to ensure consistent performance.

Applications That Make a Difference

ePTFE stent grafts and other devices are saving lives every day. Here are just a few of the key ways we’re using ePTFE to address critical medical challenges:

- Endovascular Aneurysm Repair (EVAR): Treating abdominal aortic aneurysms with precision.

- Thoracic Endovascular Aneurysm Repair (TEVAR): Addressing thoracic aortic conditions.

- Peripheral Artery Disease (PAD): Restoring blood flow in blocked arteries.

- Vascular Grafts, Frames, and Patches: Supporting vascular health in complex cases.

- Gastrointestinal Sleeves: Enhancing patient outcomes in surgical procedures.

Whether it’s creating smaller delivery systems or ensuring durability in demanding environments, ePTFE plays a vital role in improving medical device performance.

What Sets Medical Murray Apart

We don’t just use ePTFE; we elevate it. Our team combines deep materials expertise with advanced manufacturing capabilities to transform ePTFE into solutions that solve real-world problems. Here’s why customers choose Medical Murray:

- Comprehensive Conversion Capabilities: From extruded tubing and unsintered membranes to fully finished devices, we deliver exceptional results for a wide range of applications.

- Cost-Effective Innovation: By optimizing ePTFE’s production process, we ensure greater value without compromising quality.

- Collaborative Expertise: From design to manufacturing, we partner with our customers to create precision-engineered solutions tailored to their unique needs.

Let’s Build Something Extraordinary Together

At Medical Murray, we’re more than a supplier—we’re your partner in innovation. Whether you’re developing covered stents, vascular patches, or other advanced medical devices, we’re here to help you bring your ideas to life. Contact us today to get started.